This is where performance monitoring tools and models have their place. These represent the best support to the plants for the identification and quantification of even small deviations and for the diagnosis of their causes.

The information provided by these tools to the professionals of the plants and monitoring centers serves to make the best decisions regarding the maintenance of equipment and optimization of the operation.

Taking this into account, power plants that aim to prolong their lives beyond their design life can take advantage of the identification and quantification of inefficiencies in equipment, to address with greater information the necessary investments and the return that these can generate.

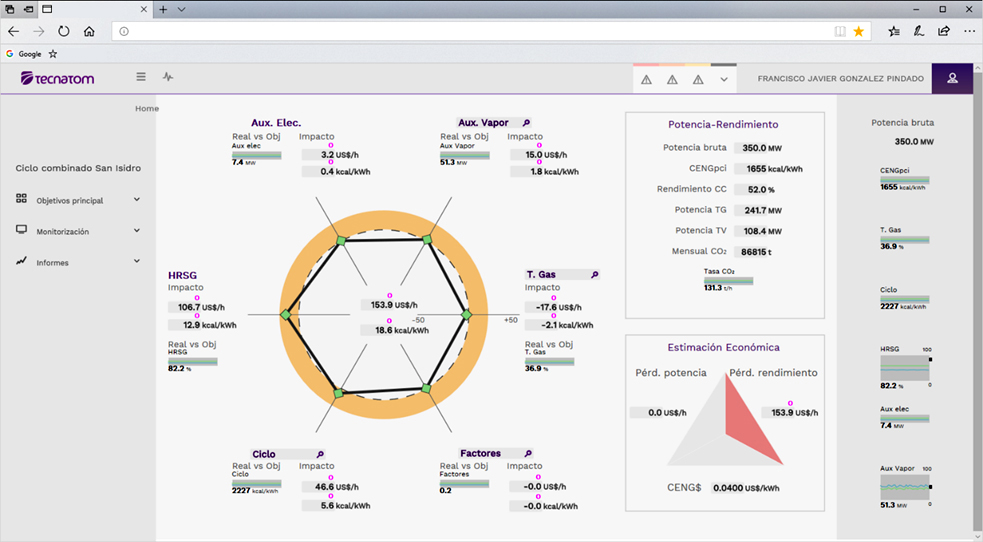

Using the TecOS SOLCEP tool, which has already been implemented in more than 50 plants of various technologies, a comprehensive performance monitoring model of a PWR plant and all its equipment has been built. The algorithms used to calculate the impact of a given deviation on the maximum power are a mixture of parametric models obtained with real data and simulation models for the most complex subsystems such as condensers and cooling towers.

This is based on the implicit concept “Benefit-based Maintenance” (BbM), as a complement to the usual maintenance strategies: time, condition and predictive. The BbM philosophy allows, with the calculation of the economic impacts of each deviation and the identification of its causes, the making of the most appropriate decisions to counteract them.

The monitoring model also provides, as an additional novelty, the functionality of Assisted Diagnosis of equipment, which allows to identify the ultimate causes of a certain deviation of performance in condensers, cooling towers, heat exchangers and pumps.

In addition, following the current trends of digital environments and Data Analysis, the model is presented with an interface based on the best practices of Human Factors Engineering, being able to be the data and indicators calculated within TecOS SOLCEP shared or transmitted to any other application within a pre-established computer structure.

Finally, this article aims to capture the opinion of the authors on the characteristics and functionalities that a performance monitoring and diagnosis tool must have in the current digital environment. This opinion is based on years of experience in monitoring and diagnosing performance deviations in power generation plants and in the development of computer solutions and simulation models.