Currently, the visual inspection is carried out by a qualified inspector with the aid of an Eddy Current equipment that detects only the presence (without geometric characterization) of defects deeper than 50 µm. These kinds of tasks are repetitive and tedious, susceptible to human error, with high visual fatigue and dose rate that, in general, it is interesting to automate.

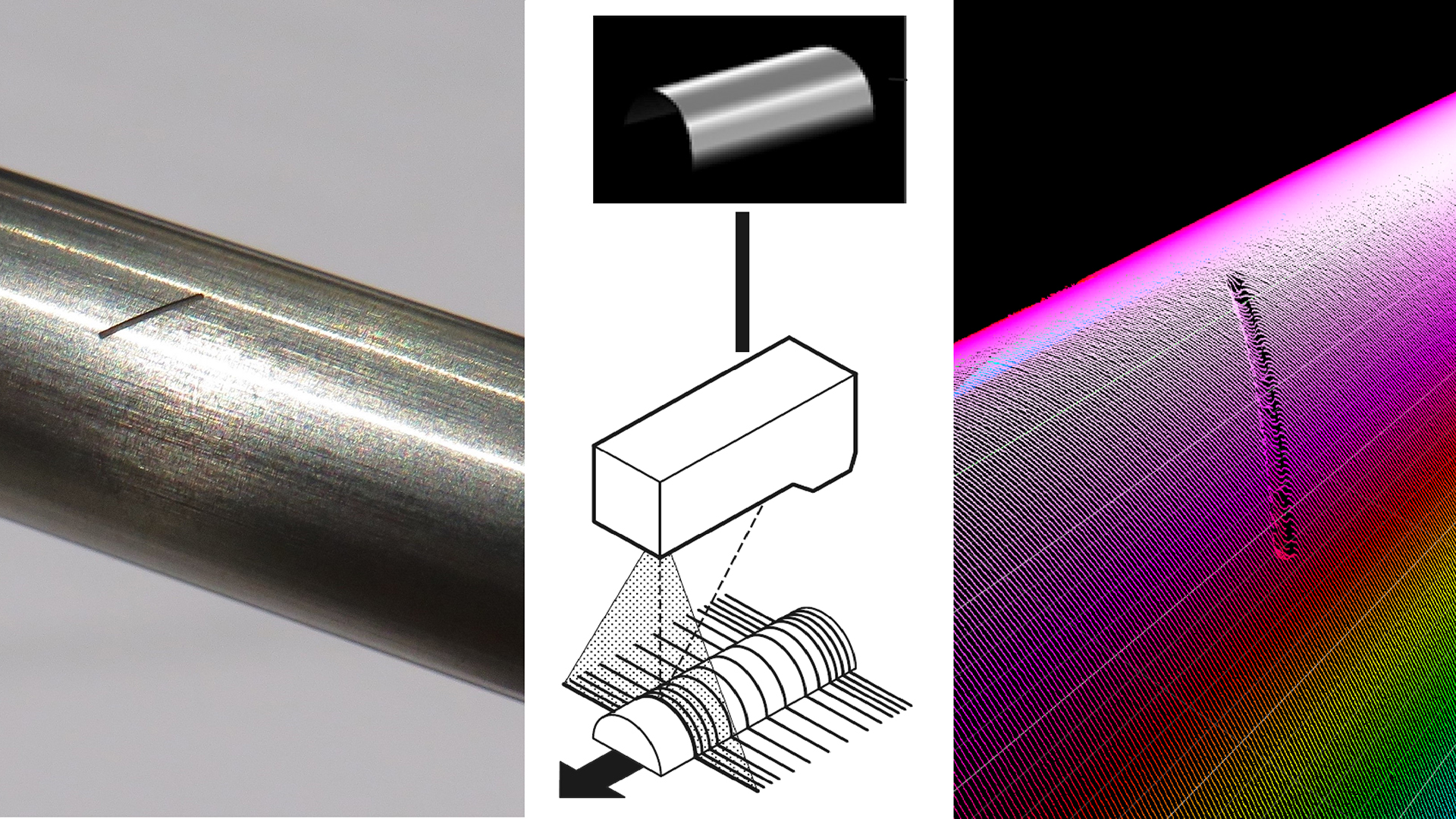

In recent years, non-contact 3D inspection has evolved, making it possible to develop an automatic application for detecting and characterizing rod surface defects. This is achieved through the acquisition of point clouds using 3D laser profilometry and the detection and characterization of defects by means of artificial vision algorithms.

This article exposes, initially and as an introduction, the motivating effect to develop the project is; subsequently, the basic principles of 3D laser profilometry, compact profilometers and the generation of point clouds, are detailed. The prototype used for the development is shown below, as well as the procedure used for the treatment of data in the automatic application. Finally the results achieved in the prototype with a standard rod with known defects characterized and the conclusions, are shown.

Patent protected application.